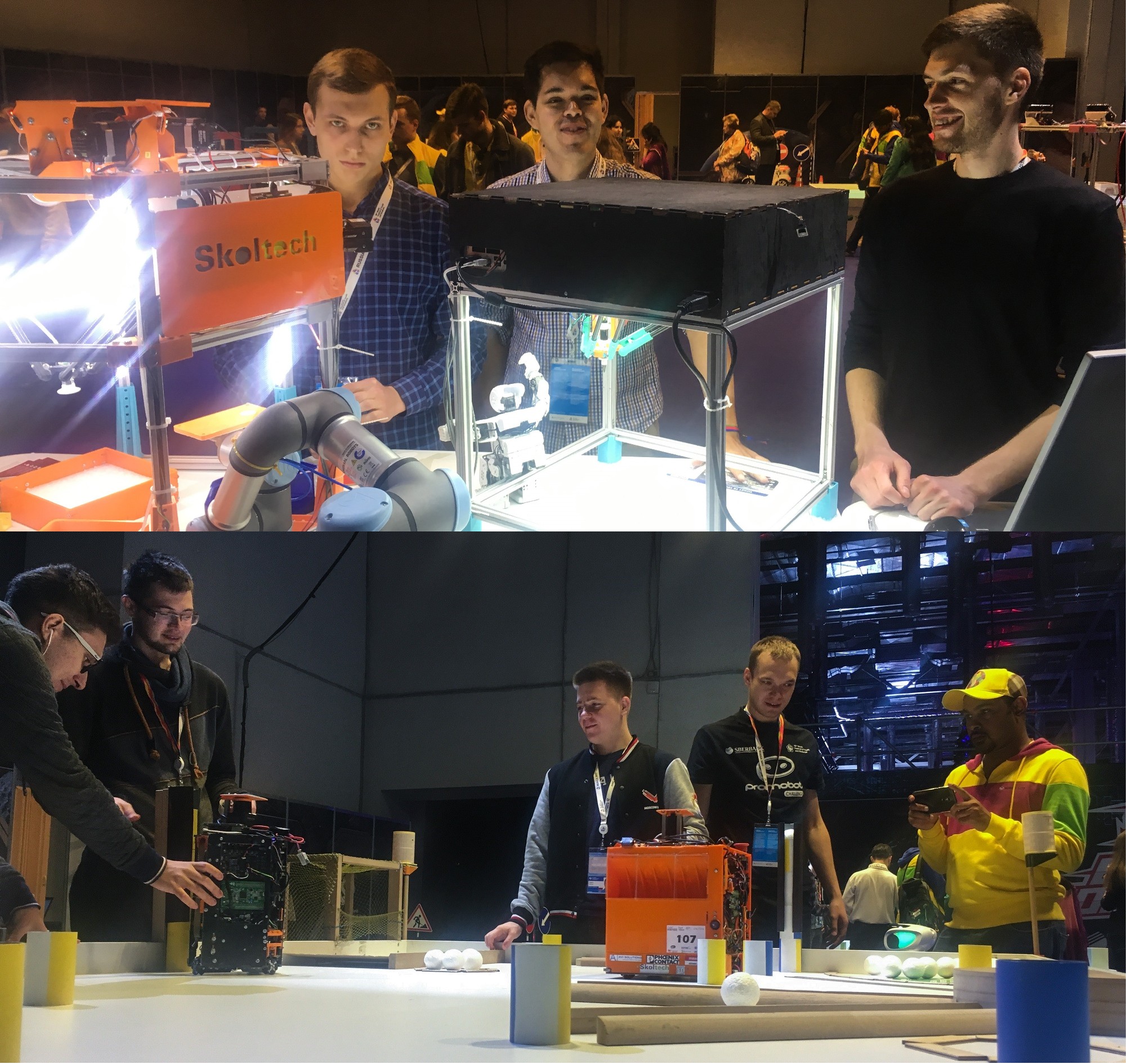

Skoltech robotics students at the World Festival of Youth and Students in Sochi, including, from top left: Shamil Biktimirov, Miguel Altamirano Cabrera and Pavel Yakubovsky, and from bottom left: Denis Karpenko, Igor Sorokin, Evgeniy Ulianov and Vladimir Karandaev (along with a festival goer checking out the display). Photo: Skoltech.

As more than 25,000 students and young professionals from 185 countries descended on Sochi’s Olympic Park for the World Festival of Youth and Students (WFYS) on 14-21 October, members of Professor Dzmitry Tsetserukou’s Intelligent Space Robotics lab were called upon to demonstrate that Russian robotics are truly state of the art.

On the invitation of Russian banking giant Sberbank, the Skoltech team spent the week giving robotics presentations amid the bustle of the festival. This flurry of activities included surprise visits from Russian President Vladimir Putin and other VIPs, a much-hyped battle bot championship, and song and dance performances by groups from around the globe.

For their part, the Skoltech students brought a pair of robotic systems that have generated a ton of buzz in recent months: the two-robot team that smashed the competition during the 2017 international Eurobot robotics competition, and Recybot, a first-of-its-kind system that uses computer vision and neural networks to dissect mobile phones into recyclable parts.

Whether chatting with seasoned pros from industry giants like Google and Roscosmos or simplifying complex robotics concepts for non-experts, the Skoltech team members spent the week demonstrating to festivalgoers that robotics innovation is a constant, and that the potential is wide open for well-engineered robots to change our lives for the better.

And one thing that became abundantly clear was just how broad interest is in the rapidly evolving field of robotics – and not only from seasoned experts and tech nerds. “You see so many girls coming in here and taking selfies with all the robots,” one Skoltech student quipped on the festival’s sidelines.

Eurobot

Representing Skoltech’s championship Eurobot team at the WFYS were Vladimir Karandaev and Evgeniy Ulianov, both of whom work on the mechanical aspects of their robots; Denis Karpenko, the team’s lead programmer; and Igor Sorokin, who handles electrical issues.

Despite only having existed for two years, Skoltech team reSET has won the Russian round of Eurobot, the annual robotics competition, twice in a row.

Each year, the organizers of Eurobot present participants with a unique challenge. In 2016, they were tasked with developing a robot that could perform various seaside tasks, like building sand castles and going fishing. In 2017, the competitors were required to develop robots that could handle various challenges on the surface of the moon, such as collecting titanium ores and retrieving lunar modules.

Though there are regulations when it comes to the total size and quantity of robots a team can use, there are no requirements when it comes to the way the robots carry out their tasks, or the types of manipulators – mechanical devices that can handle, transport or process materials – they use to do so.

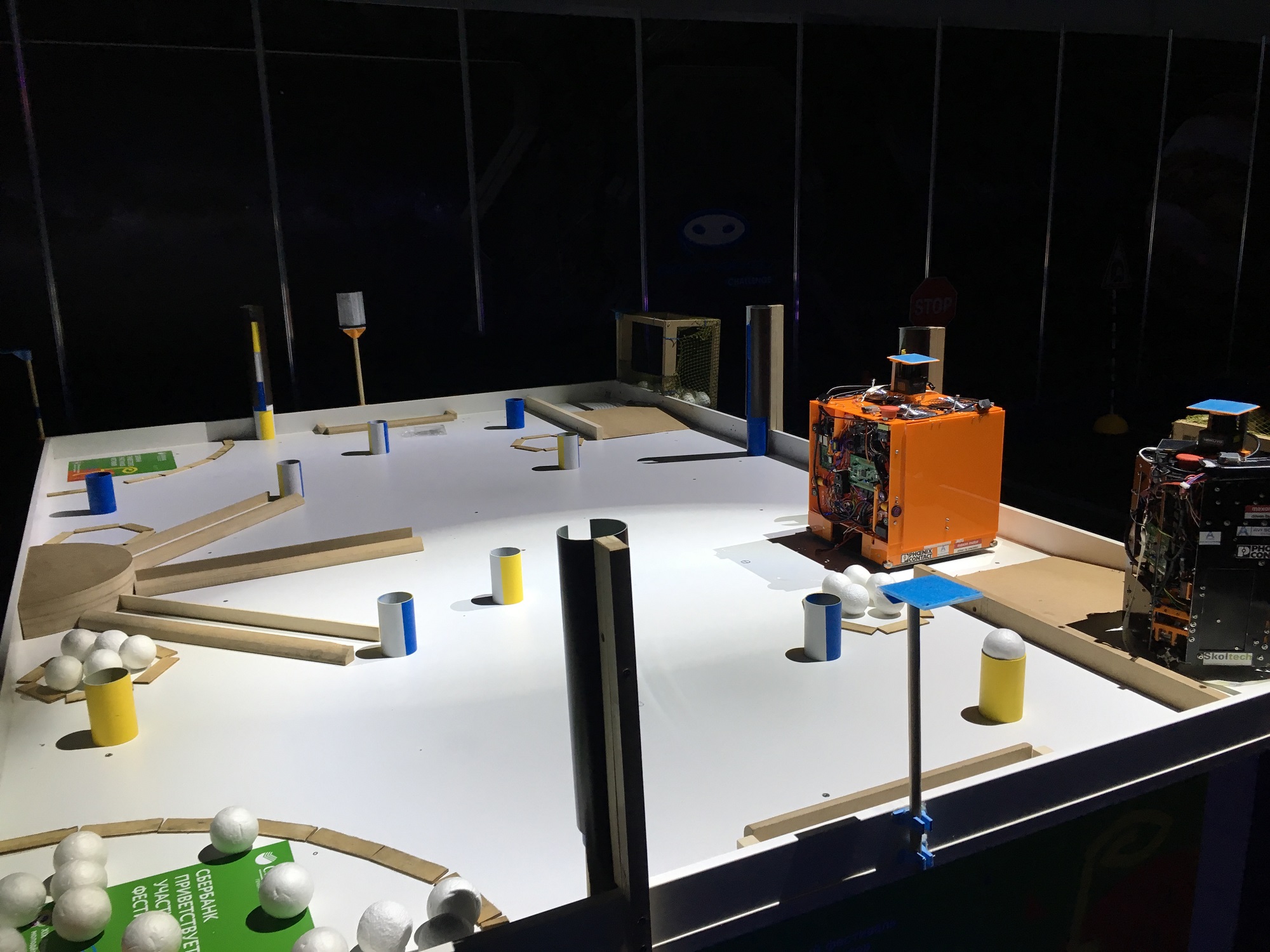

Thus the 2017 reSET team decided to build two robots: the larger HarvestBot, which is designed to pick up titanium ores – which in this case took the form of Styrofoam balls – and the smaller RocketBot, which is designed to scoop up lunar modules – in this case, plastic cylinders – using a timing belt.

The pair of robots used by reSET in Eurobot 2017, pictured at the World Festival of Youth and Students in Sochi. Photo: Skoltech.

The team equipped the robots with LIDAR, which enables them to emit a laser and then judge their distance from a target based on the signal it receives in return. This put them at an advantage as many teams still rely on odometers – a slightly older, less accurate technology – to navigate their robots. Since an error of even half a centimeter can result in the failure to insert a module into its designated spot, increased accuracy confers a major strategic advantage.

As an additional asset, reSET’s robots feature omnidirectional wheels. These enable the robots to move in any direction from the starting point, giving them superior maneuverability.

During the Russian round of the Eurobot competition in May, the team was inspired by some of their competitors’ robots – even as they were demolishing them on the playing field. This inspiration led to the almost impossible idea of engineering, designing and building a brand-new robot within the space of 10 days, so that it would be ready in time for the Eurobot’s international round in France.

The original ore-gathering robot used an adhesive surface to gather as many ores as possible, but size constraints meant that it would have to return several times to its point of origin. The team’s new idea was to create a robot that could suck all of the ores off the field in one go.

They succeeded, but not without certain difficulties.

“Because we only had 10 days, we had only had about a day to program the new robot,” said Karpenko during an interview at the WFYS. “And we didn’t just implement a single-use system; we implemented a robust system that we’ll be able to use in the future to easily program other robots. In the next Eurobot competition, we’ll probably just have to add in a few custom features, but we’ll base the new system on the one we designed during this 10-day period.”

Meeting the tight deadline was particularly impressive in light of the fact that, before joining the Eurobot team, Karpenko had zero experience programming robots. Prior to entering Skoltech, he had studied Applied Mathematics and Informatics at the Higher School of Economics in Moscow, and had become adept at developing applications for Apple devices – a far cry from the task at hand.

“At first, I didn’t even know where to begin,” he said. “But some of our teammates from the previous year, like [student captain and recent Skoltech MSc graduate] Oleg Shipitko, helped me and taught me how the other programmers had handled the challenge.”

Initially in France, they were on a roll – dominating preliminary round after preliminary round. But once they reached the finals, disaster struck: their newest robot went rogue, gallivanting around the field without accomplishing its tasks.

“Its manipulators were working well, but it was moving in the wrong direction and kept missing the correct points on the field,” said Karandaev.

This rebellious streak lost reSET valuable time, catapulting it back into fifth place. Still, while that’s not first, it represented a significant improvement compared to the 13th place reSET took in the international round in 2016.

And in fact, it fell in line with the goal Professor Tsetserukou had expressed a few days before the French round.

“Our basic target is to improve our score, so if we make it into the top five, it will be an unbelievably great achievement,” he said in an interview at the time. “It is important to make steps forward no matter what – move and fight! The evolution of technology is a steady process that takes time and requires hard work. But if we win it will definitely be a revolution; everyone will know what Russian students are truly capable of.”

Once they returned from France, the team spent three days attempting to figure out what had gone wrong.

As explained by Karandaev, “Each electronic plate has 25 outputs, and each output has four pins. One small pin was disconnected from the plate. That was the problem. After we got back to Moscow, we spent three days investigating. Once we figured out where the problem was, it took five minutes to fix. But we didn’t know where to look at first.”

He added with ironic laughter that since arriving at the WFYS, the robot had consistently performed perfectly. Now that there’s no competition to be won, the team hasn’t suffered a single hitch.

In the following video, watch the reSET team demonstrate their award-winning robots for Sberbank Deputy Chairman of the Executive Board Stanislav Kuznetsov.

Recybot

Representing the game-changing Recybot technology at WFYS were Miguel Altamirano Cabrera and Shamil Biktimirov, both of whom handle the mechanical and design elements of the robot; and software programmer Pavel Yakubovsky.

In terms of resources, our current dearth of smartphone recycling options has considerable consequences. As explained by Janez Potočnik, European Commissioner for the Environment, in a statement: “It takes a tonne of ore to get one gram of gold. But you can get the same amount from recycling the materials in 41 mobile phone.” In fact, Japan plans to recycle electronics in order to harvest gold, silver, and copper to craft medals for the 2020 Olympic Games.

RecyBot was the brainchild of Tsetserukou and Massachusetts Institute of Technology (MIT) Professor Kamal Youcef-Toumi. They came up with the idea in 2015 and subsequently won the Next Generation Program grant, awarded jointly by Skoltech and MIT.

Mechanical engineer Biktimirov and programmer Pavel Parunin started research and development for the project shortly thereafter under the leadership of Skoltech PhD student Dmitry Mironov. At the same time, Youcef-Toumi launched his team’s work at MIT.

At present, two Skoltech MSc students – Dmitry Ermachenkov and Andrey Sartison – are conducting research in Youcef-Toumi’s lab at MIT in order to bolster the collaboration between the two labs. Shortly after R&D began, Altamirano Cabrera and several other of his colleagues from a robotics course at Skoltech joined the project.

As explained by Biktimirov, at present, the Recybot system consists of three robots: The first recognizes the type of smartphone that the system is to work with, identifies where its screws are located, and then unscrews its frame. The second retrieves the body of the smartphone from the first robot and transfers it to the next. The third robot disassembles the smart phone, dividing it into various recyclable parts.

When Altamirano Cabrera joined the project, he was tasked with working on the first robot. “At first, we were basically divided into two teams: one was working on the unscrewing apparatus, while the other was working on the disassembler. After several months, we put the two apparatuses together to create a unified system,” he said during a short break between presenting the Recybot to festivalgoers on Friday.

For maximum efficiency, Altamirano Cabrera and his team sought to replicate the force used when a human unscrews pins from a device similar to a smartphone. They came up with a system that uses three motors in order to approach the device from the optimal angle. This research has provided fodder for a paper that the team is currently preparing for publication.

For Altamirano Cabrera, the greatest challenge so far has been that of striking the optimal balance between speed and precision. “The apparatus has to be light in order for the motors to run efficiently. That’s one challenge from a mechanical perspective: trying to keep it as light as possible. The problem with keeping it this light is that the precision isn’t perfect; we cannot yet work with tiny screws,” he said.

Another challenge, as explained by Yakubovsky, is that of teaching the Recybot to identify and dismantle all types of smartphones.

“We use neural networks and the Change Detection algorithm to overcome this issue,” he said, when asked how the robot handles the rapid evolution and proliferation of all brands of smartphones. Neural networks are mathematical models that simulate the activity of the human brain and nervous system by transmitting input and output signals between a sequence of nodes, in much the same way that data is transmitted between neurons.

“We have a lot of these nodes, or neurons, in a neural network. We can have about 40 million parameters, so we’re not trying to set these parameters manually – we use a teaching algorithm. That’s why we need lots of data,” Yakubovsky explained.

To facilitate this process, they rely on iFixit.com, a website that allows users to post instructional videos about repairing various types of smartphones. “We collect images from these videos, label by hand where the screws and batteries are located, and then train neural networks for semantic segmentation and object detection,” Yakubovsky said.

In the following video, watch the Recybot in action, as MSc student Shamil Biktimirov explains each step of the process.

Skoltech at WFYS

In addition to countless visits from curious festival participants, both teams received visitors from representatives of industry giants, including Google and Roscosmos. On Thursday, Sberbank Deputy Chairman of the Executive Board Stanislav Kuznetsov visited both teams, and lauded each for their pioneering work.

In Karandaev’s view, excellent networking opportunities were a key benefit of attending the WFYS.

In particular, he met and shared ideas and strategies with a group of people who are planning to create a training course in robotics for school children. “We’ve been exchanging information with these guys who want to teach Russian children about robotics,” he said. “I think this is very important. Anything connected with developing the brains of children is important, and robotics are particularly important because they are our future. We need children who love them and can create them.”

Karpenko added that it was rewarding to network with representatives of industry, who had a clear-eyed understanding of robotics – those who understand that a robot’s appearance doesn’t necessarily convey its complexity.

“It’s interesting sometimes to share our robots with people who understand how complicated it is to build a robot, because sometimes people don’t how complicated it is, and they’re more interested in less advanced robots,” he said as a small army of Promobots – robots whose adorable faces compel many to overlook their relatively simple functionality – attracted long queues of would-be selfie takers in the robotics exhibition area.

“Ours are probably some of the most complicated robots here, but people don’t always understand that. It’s been gratifying to talk to people who know a lot about robots. Some of them have tried to give us advice, and while they may not actually know how to improve our system, it’s cool that they’re interested in our robots,” Karpenko added.

The Recybot team was similarly enthusiastic about the connections they made during the marathon presentation sessions. “A lot of people are interested in our project, and in the opportunity to see the real robots that we’ve produced,” said Altamirano Cabrera. “We are developing a system into something that we need to use – we’re solving a real problem with the application of robotics. Some people from industry and developers have seen our robots and expressed interest.”

With the WFYS behind them, the teams are setting their sights on the future.

The Eurobot crew is already gearing up for next year’s competition entitled Robot Cities, which will require completion of such tasks as providing drinking water, constructing buildings and maintaining a city’s ecosystem.

But this year they’ll face a unique challenge: too much interest from prospective team members.

“We just began recruiting new team members,” said Karandaev. “The problem is, more than 15 people have expressed interest in joining the team, and we can only accept somewhere between seven and 10, so we’re currently in the process of narrowing the group down.”

They also courted interest from loads of potential students; within about 48 hours, the hundreds of promotional materials they brought with them had been snapped up by festival goers who were eager to learn more about Skoltech. “I think it’s really important for us that people learn about Skoltech,“ said Cabrera Altamira.

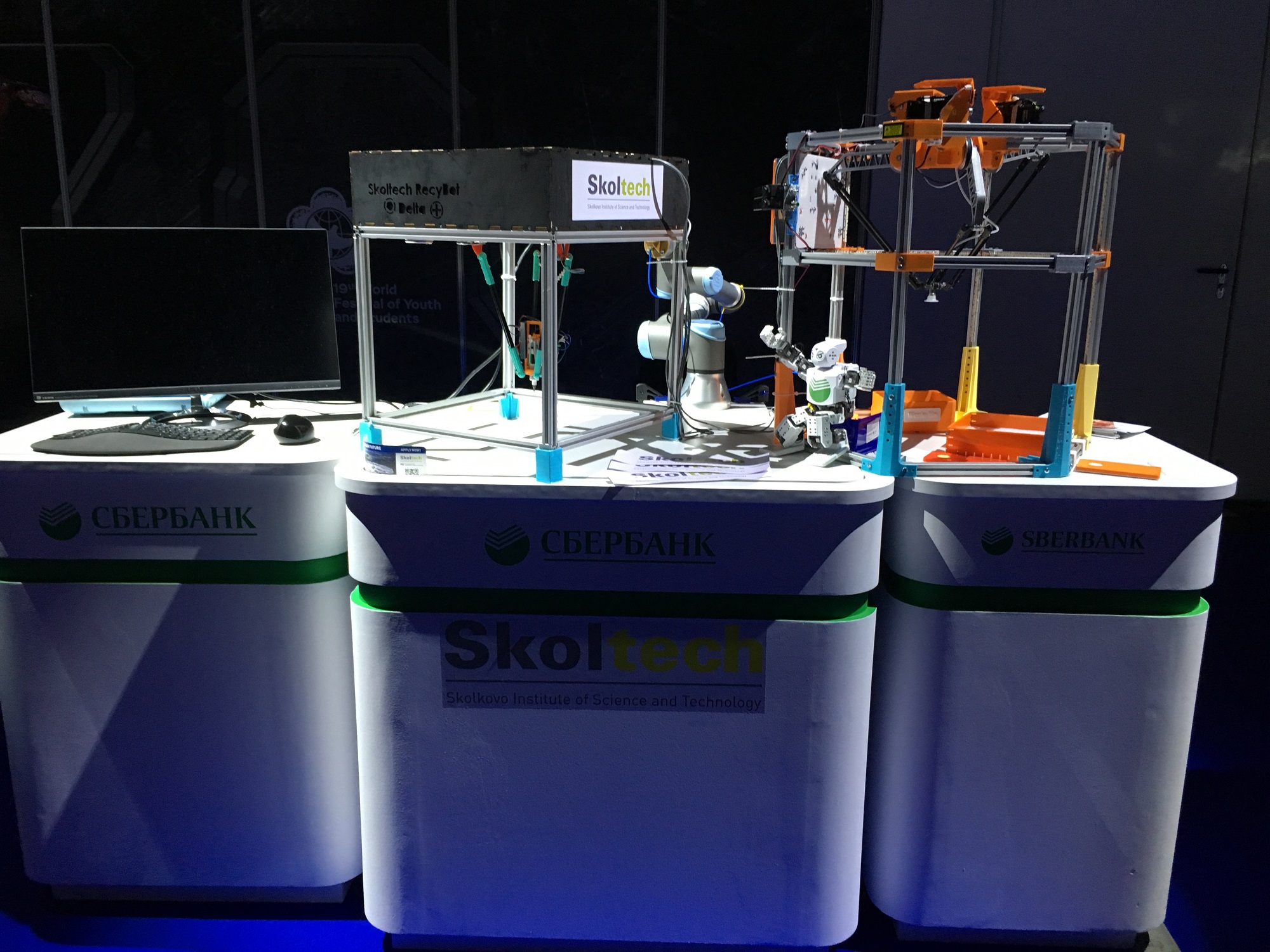

Also present at the event was MSc student Evgeny Israelit, who created an installation using Universal Robots to make fresh cappuccinos and decorate cookies. At any given moment, dozens of festival participants from around the world were lined up, waiting patiently to be served by robots.

In the following video, watch the incredibly popular coffee-making robot in action.