A striking trend in modern architecture, freeform structures are one-of-a-kind buildings of unconventional shapes: museums, stadiums, luxury hotels, exhibition pavilions, or universities, for that matter — you need not look any further than the Skoltech campus!

Today reinforced concrete is the go-to material for these impressive constructions, with their domes, vaults, and complex facades. But fiber-reinforced polymers are a promising alternative. Sure, they are more expensive to produce, but the maintenance is cheaper, because they do not rust and need not be painted. They are also light and sturdy, unlocking new possibilities for architectural expression — for example, wider spans without intermediate supports.

To make this happen, the existing tools for building design and modeling have to be reinvented, because they are geared toward traditional materials such as reinforced concrete or steel. This is what the scientific team of the Laboratory of Composite Materials and Structures from Skoltech Materials led by Associate Professor Alexander Safonov and their colleague from the University of Granada are beginning to do in their study reported in Composite Structures.

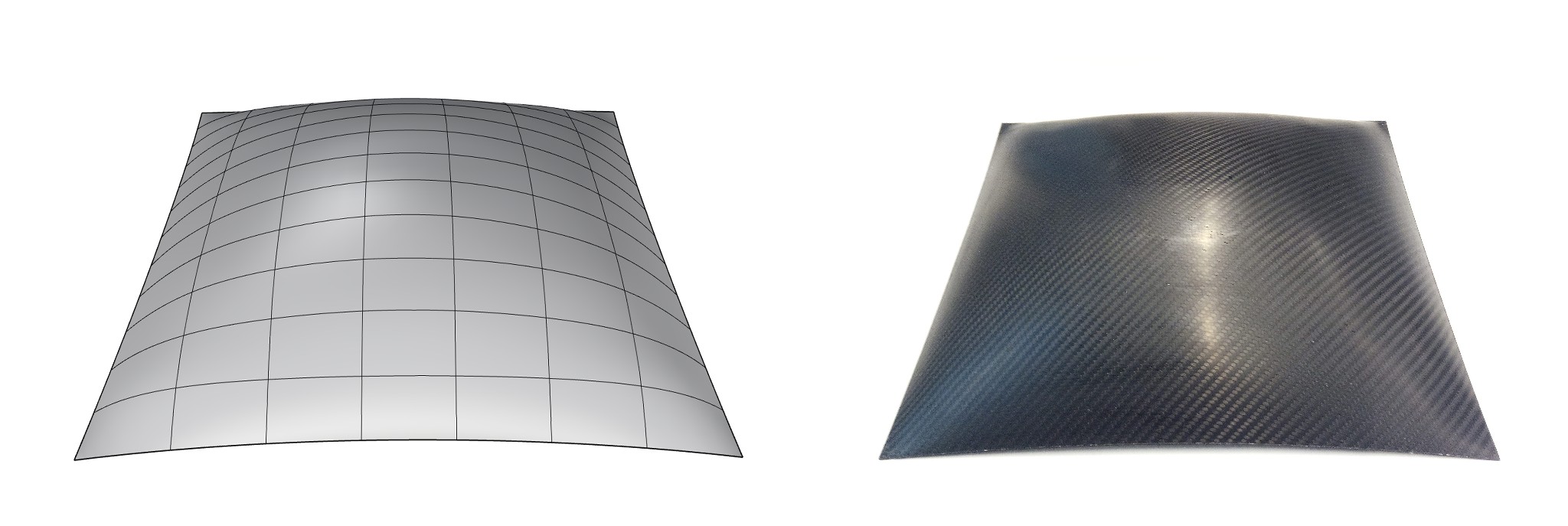

The geometric shape (left) and the corresponding real-life model made of fiber-reinforced polymer investigated in the study. The size of the model is 30 by 30 centimeters. Credit: Anastasiia Moskaleva/Skoltech

“It is tempting to just transfer what we do with reinforced concrete to polymer composites. But that is mere mechanical reproduction of what we’re used to, without due regard for the unique nature of the new material and its potential,” the study’s lead author and Skoltech Materials PhD student Anastasiia Moskaleva commented. “So in this study, we do it properly and go all the way from design to manufacture without pretending that we’re dealing with concrete. We focus on one particular structure shaped as a curved surface, which we investigate in miniature.”

The surface in question is called a form-found shell structure. It sounds technical, but it’s a kind of shape that comes up in freeform architecture in some domes and vaults. The researchers completed the full cycle by designing the structure, fabricating it as a 30-by-30-centimeter lab sample, and then testing it under artificial stress in an experiment. They also modeled the shell’s mechanical properties mathematically.

In this study, the team emphasized the design stage. There is no tried-and-tested technique for designing composite structures of this kind, so the researchers adopted the force density method. It is used for similar structures made of concrete, wood, and steel but has so far not been applied to composite structures.

“It is only recently that this method got its formal mathematical description, but it is rooted in experiments such as those done by Antoni Gaudí. He used to derive highly efficient forms by suspending models in the air to let them sag under their own weight and then inverting the shape they assumed. In a way, he let gravity do the work in a form-follows-force sort of way,” Moskaleva said. “Basically, we specified that we wanted a structure that would rest on four supports and bear its own weight in an optimal way, and the method led us to this shape.”

The structure was then manufactured as a small-scale sample using what’s known as vacuum infusion in the Laboratory of Composite Materials and Structures at Skoltech Materials. This involves laying sheets of carbon fiber over a rigid framework that gives them shape in an airtight pocket, covering the structure with epoxy, and causing it to soak the fabric by manipulating pressure. After a day in the airtight compartment, the sample solidified and was ready for mechanical tests.

“But first we ran numerical modeling to predict the structure’s mechanical properties: how it would behave in the test under mechanical load,” Moskaleva said. “This gives us reason to believe the model we chose could be used for similar structures in the future, because it indeed matched the experimental observations fairly closely. In the experiment, we kept loading the structure from above until loss of stability.”

The study thus lays the foundation for designing and modeling curved-surface construction elements made of polymer composites. Eventually, they could become part of the freeform architecture toolkit. The shape itself of a double-curvature shell is more efficient for bearing a load, compared with, say, a flat concrete slab, the researchers explain. But if we could also tap into the superior properties of polymer composites, the creative possibilities are immense. Between lower maintenance costs and outstanding mechanical properties, this could even be more cost efficient, not to mention the expressive potential.

Contact information:

Skoltech Communications

+7 (495) 280 14 81